„Alpha Omega” is one of the leading producers of equipment and consumables for neurosurgery and for neurophysiological research. Since it produces clinical devices, they have to pass certification, including FDA. I am proud that I was working in this company and participated in developing world’s finest hardware and software that provides us with knowledge about the brain functionality and helps patients to return to normal life.

Work Experience

- Started in September 2019, finished in March 2024.

- Position: DSP Software Expert, Embedded Software Developer.

The hardware part was aggregating data from the electrodes submerged into the brain tissue, filtering it, denoising, and forwarding to the neurosurgeon’s or neurophysiologist’s computer, where the UI was displaying it. The neurosurgeon decided whether to perform stimulation on any of the electrodes, and the hardware part received this command, parsed it and configured the system for the stimulation. I was responsible for writing the code of the hardware part.

I took part in several projects, mostly developing new neuroscientific solutions. Here I’ll describe some challenges I’ve successfully resolved.

Image credit: Alpha Omega.

My work on the „AlphaRS” system

„AlphaRS”, standing for „Alpha [Omega] Recording System”, is one of the most advanced solutions for neurophysiological research. It was a vended product, but also it served as the basis for several generations of systems, each adapted to a different task and enhanced its unique advantages, therefore the customer could choose the one that serves him best.

The „AlphaRS” solution was loosely based on the code from AlphaLab SNR, the previous generation of neuroscientific research system provided by „Alpha Omega”. However, during the process of adaptation to the new hardware, the code had been changed significantly. For example, the DSP used in „SNR” had only three cores, whether the DSP used in „AlphaRS” has 8 cores with higher frequency; therefore each core in „AlphaRS” was assigned a specific task, — some are gathering data from the electrodes, some are running denoising and filtering algorithms, and some pack the data and send it to the surgeon’s computer. The load balancing is achieved by distributing the data received from the contact pads between several cores.

Interesting challenges I’ve successfully completed while working on this project:

Reducing boot time of „AlphaRS” hardware

Implementation of the licensing mechanism

Image credit: Alpha Omega.

My work on the „AlphaRS Pro” system

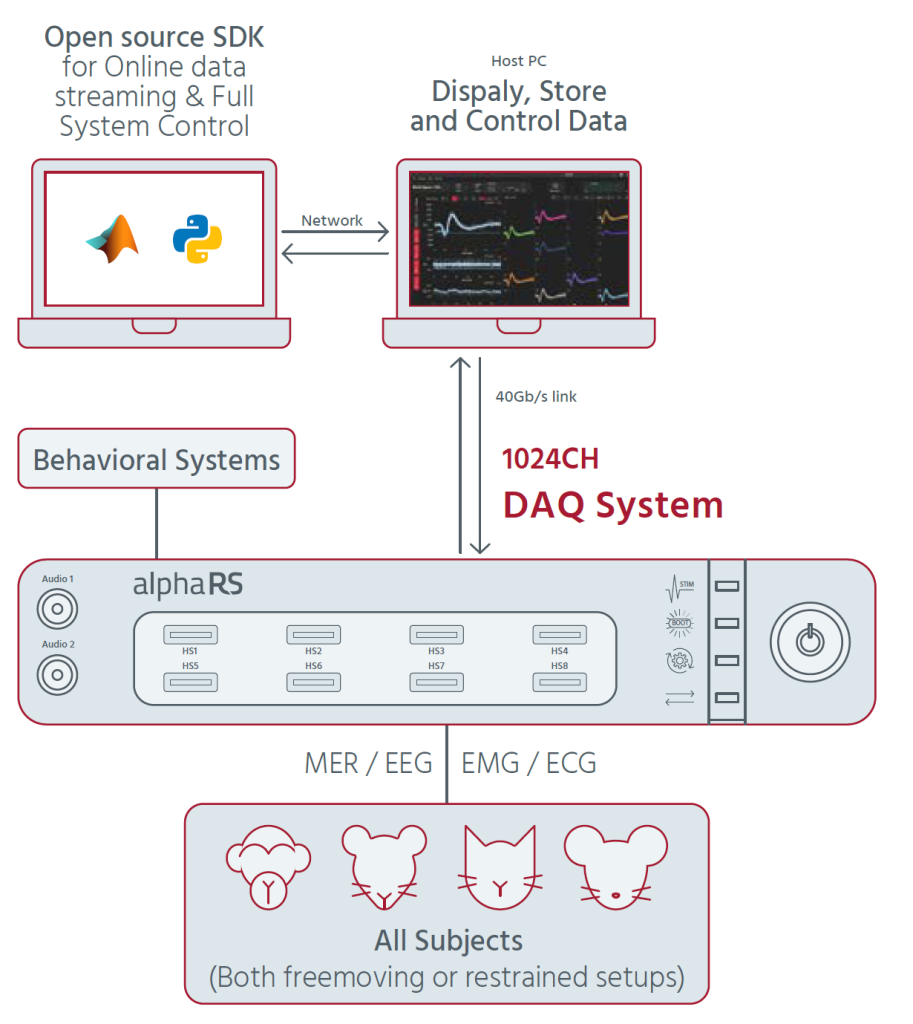

„AlphaRS Pro” is the next generation of the „AlphaRS” family. It supports 1024 contact pads between the neurons and the electrodes, which produces a lot of data, — no, really, we’re speaking about gigabytes per second. Therefore, the solution of transferring the gathered data through Ethernet connection was not feasible anymore. I evaluated the possibility to use an Ethernet connection with more capacity, but the DSP used in „AlphaRS” also reached its limits, both in terms of memory and in terms of computing power, so the solution had to lie in an entirely different plane.

It was decided to use a different approach: gather the data in the external box, just like before; digitize it via A2D converters, but instead of using DSP — transfer the data directly into the main computer of the neurosurgeon via Thunderbolt connection, which connects the data acquisition hardware in the external box directly to the PCIe bus of the main computer. Then, by registering the hardware in Windows® with appropriate driver, the data acquisition device receives access to the computer’s memory controller, and we can use DMA in order to transfer the gathered data. By using PCIe connection with two lanes, transfer speed of up to 40 Gb/s can be achieved.

Image credit: Alpha Omega.

All the rest of the processing is performed in a bunch of threads on the neurosurgeon’s computer, partially in the graphic card, and double buffering is used to transfer data between the driver and the UI. UI obtains the data from the RAM, just as before, — but much, much more data, — so the amount of required changes in the UI was reduced to absolute minimum.